Chilled Water Coils

Chilled Water Coils for Efficient Cooling

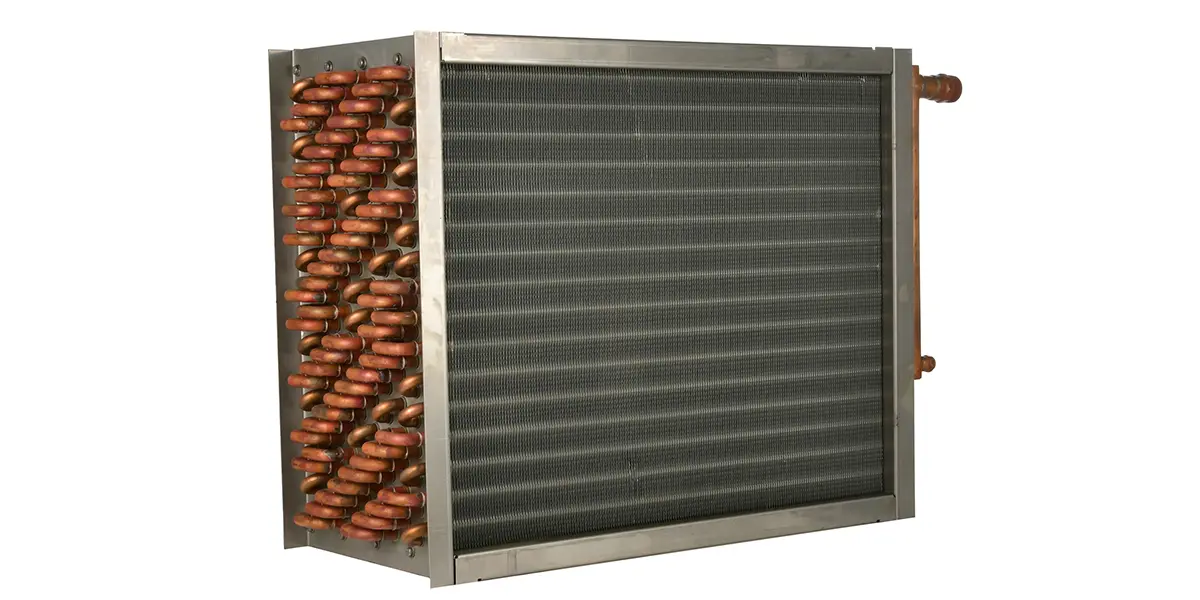

Chilled water coils play a critical role in HVAC systems for industrial and commercial facilities where high-capacity cooling is required for equipment operation and comfort. Precision Coils manufactures replacement, OEM, and design-build chilled water coils to customers’ exact specifications.

Custom Specifications for Chilled Water Coils

There are various factors to consider when ordering a replacement or OEM chilled water coil. As a chilled water coil supplier for more than 25 years, Precision Coils’ staff have the expertise to help customers develop coils matching their system’s design requirements and performance goals. These customization options include:

- Cooling Capacity: Matching a coil’s cooling capacity to an HVAC system’s cooling load is necessary for efficient coil operation.

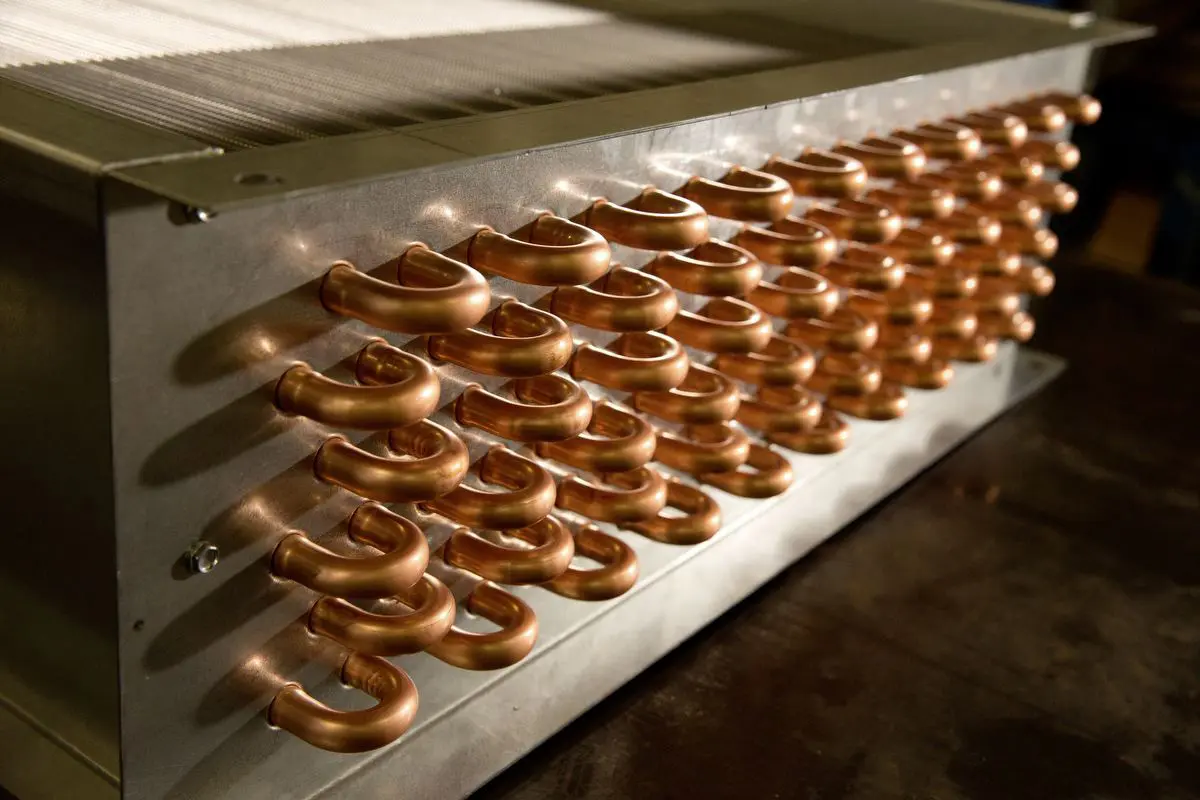

- Material Selection: Materials available for constructing chilled water coils include galvanized steel, stainless steel or copper casings, copper tubing with aluminum or copper fins, and special anti-corrosive coatings.

- Fin Density: While a higher fin density increases the coils’ heat transfer, it can also result in greater air resistance or pressure drop.

- Circuiting and Rows: The type of tube circuiting and number of coil rows impact coil performance and the decrease in air pressure. Chilled water coils from Precision Coils can be built with 1–12 rows.

- Connections: MPT, FPT, sweat, or Victaulic connections are available in copper, steel, or brass.

Direct Order Entry in PC Select

Precision Coils products can be purchased directly from PC Select using Direct Order Entry (DOE). DOE offers accelerated order processing and faster access to order acknowledgements, sales order numbers, and estimated ship dates to complete projects efficiently. Contact your sales representative to set up an account.

Chilled Water Coil Applications

Chilled water coils are primarily used in larger commercial facilities to meet high cooling demands. Some sites that use chilled water coils include:

- Office Buildings

- Airports and Transportation Hubs

- Hospitals and Healthcare Facilities

- Data Centers

- Schools and Universities

- Industrial Plants

Benefits of Chilled Water Coils

- Energy Efficiency: Chilled water coils readily integrate into central chiller systems, which offer greater energy efficiency than direct expansion (DX) cooling systems.

- Scalability: HVAC systems for larger properties such as schools, offices, and hospitals utilize chilled water coils for their precise temperature control.

- Humidity Control: Chilled water coils cool air below the dew point, helping remove moisture while enhancing indoor air quality and comfort.

- Design Flexibility: Chilled water coils come in various sizes, materials, and fin configurations, offering full customization to handle specific airflow rates, space constraints, and cooling requirements.

As a leading chilled water coil manufacturer, Precision Coils’ experience and commitment to customer satisfaction enables us to deliver premium, customized coils with rapid, responsive service unmatched by our competitors.

Right Fit. Right Now.