Standard Steam Coils

Steam Coils for Efficient Heating

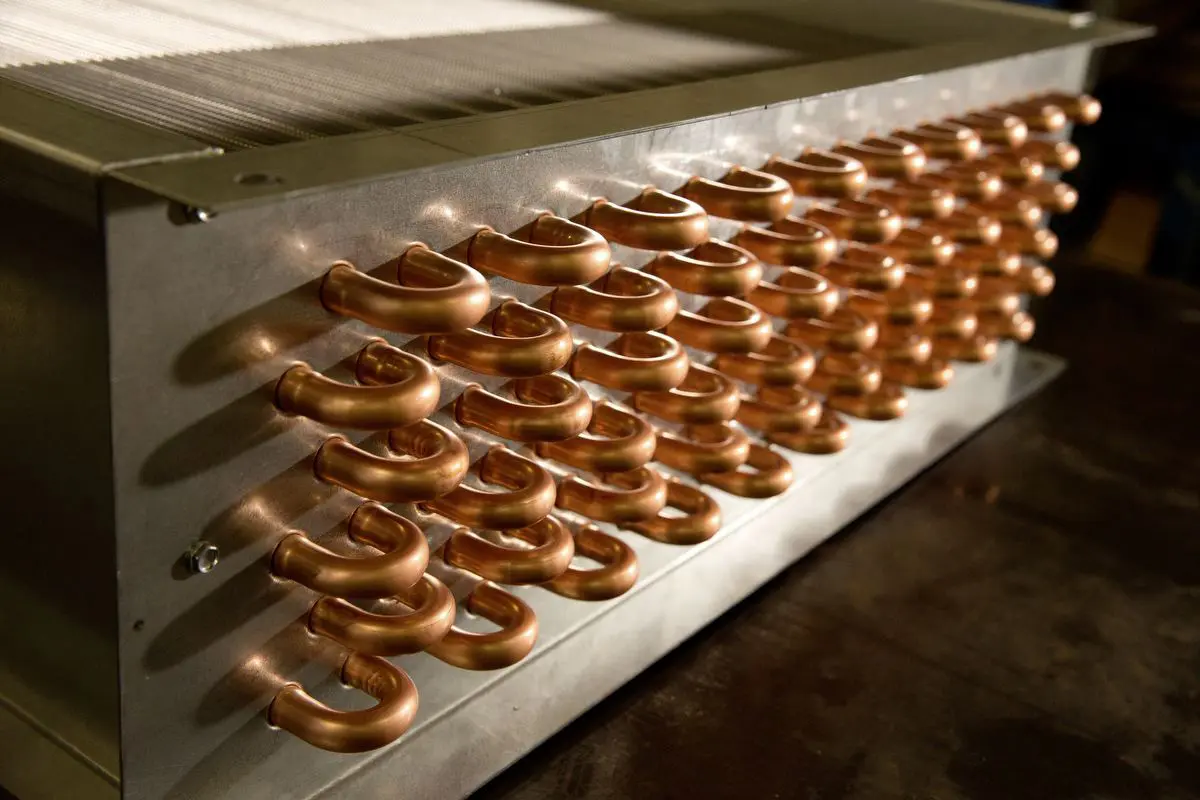

Unlike non-freeze steam coils, standard steam coils are built with single pass tubing in which steam enters, condenses, and exits as condensate. For situations where freezing isn’t a significant risk, the custom steam coils manufactured by Precision Coils provide a means of efficiently increasing air temperatures in ventilation systems, air handling units (AHU), ductwork, and other commercial and industrial HVAC applications.

Specifications for Proper Steam Coil Selection

If you’re looking for precision-engineered steam coils, Precision Coils’ experience is invaluable in selecting the proper steam coils for specific HVAC requirements. Our engineering team takes multiple factors and specifications into consideration when designing custom coils:

- Steam Pressure and Temperature: The design of steam heating coils must correspond with the temperature and pressure of the existing steam system. Higher pressures necessitate different coil construction.

- Airflow Requirements: The air velocity and volume of an HVAC system is used to calculate the size of the steam coil and number of rows required.

- Material Selection: Replacement steam coils with copper tubing and aluminum fins are a common construction offering high heat transfer, but specific coatings may be necessary for steam coils in corrosive or high-humidity environments.

- Condensate Removal: Ensuring your standard steam coils have proper condensate trapping and drainage is critical for preventing corrosion and maintaining heat transfer efficiency.

Direct Order Entry in PC Select

Precision Coils products can be purchased directly from PC Select using Direct Order Entry (DOE). DOE offers accelerated order processing and faster access to order acknowledgements, sales order numbers, and estimated ship dates to complete projects efficiently. Contact your sales representative to set up an account.

Steam Coil HVAC Applications

Standard steam coils are used in HVAC applications where freezing temperatures are not a major concern. Provided there’s no great risk of freezing, steam coils are used in the following applications and facilities.

- Commercial HVAC Systems

- Industrial Process Air Heating

- Institutional Facilities such as Schools or Hospitals

- AHU and makeup air units

- Drying Processes in Manufacturing

Benefits of Standard Steam Coils

- Cost Effective: Steam coils cost less than more specialized coils due to their simple yet effective construction.

- Efficient Heat: Steam heating coils rapidly increase air temperature for process heating or to provide more comfortable temperatures.

- Versatility: Replacement steam coils can be constructed in various sizes and configurations to integrate with multiple types of HVAC systems.

- Low Maintenance: Steam coils utilize fewer components, resulting in easier cleaning and maintenance compared to more specialized coils.

If you need replacement, OEM, or design-build standard steam coils, Precision Coils offers expert construction with fast, exceptional service. Our decades of experience manufacturing heat transfer products ensures our steam coils are constructed using optimal materials and match the airflow and pressure of your HVAC system for effective condensate drainage.

Right Fit. Right Now.