Coil Specifications

Specifications for Replacement, OEM, and Design-Build Coils

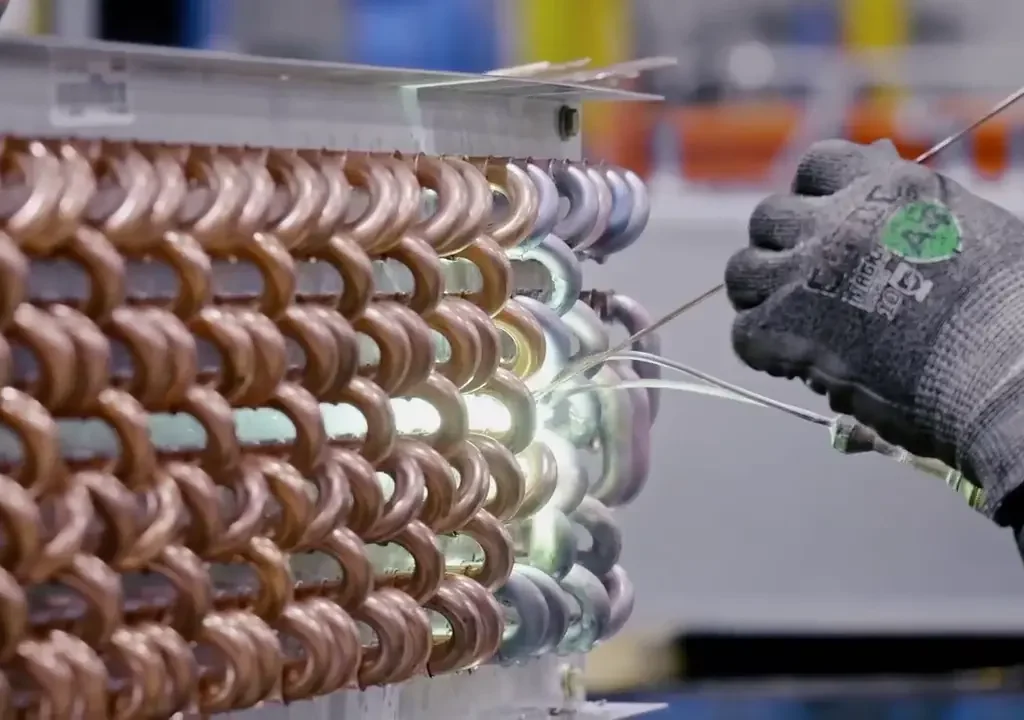

The following coil specifications detail maximum operating temperatures and pressures, fin diameters and spacing, as well as available connection types, testing requirements, and tubing options. These comprehensive specifications enable our customers to create custom coil designs to meet their specific HVAC system requirements. All of Precision Coils’ replacement, OEM, and design-build coils are constructed to the highest quality standards backed by our success over 25 years in business.

Precision Coils Custom Specifications

The following list of specifications is applicable to Precision Coils’ water, steam, evaporator, and condenser HVAC/R coils.

Design Pressures and Temperatures

Coil shall be designed to withstand the following maximum operating pressures and temperatures:

- Water Coils — 250 PSIG / 300°F

- Steam Coils — 125 PSIG / 353°F

- Evaporator Coils (3/8″ Coils) — 400 PSIG / 300°F

- Evaporator Coils (1/2″ & 5/8″ Coils) — 250 PSIG / 300°F

- Condensing Coils (3/8″ Coils) — 600 PSIG / 300°F

- Condensing Coils (1/2″ & 5/8″ Coils) — 300 PSIG / 300°F

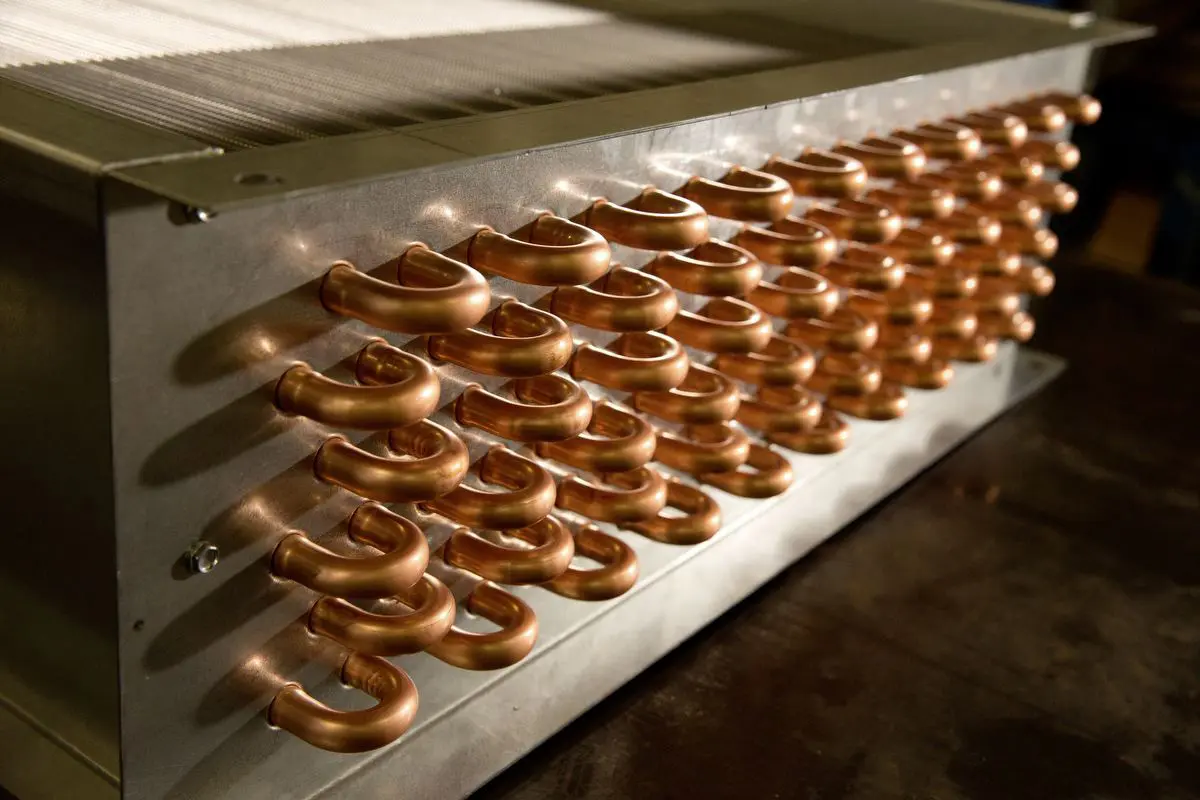

Fins

Coils shall be plate fin type construction providing uniform support for all coil tubes. Coils are to be manufactured with die-formed aluminum or copper fins with self-spacing collars which completely cover the entire tube surface.

Thickness:

0.0060″ +/- 5% unless otherwise specified

Tube Holes:

- 625” diameter spaced 1-1/2” equilaterally

- 500” diameter spaced 1-1/4” equilaterally

- 375” diameter spaced 1.” equilaterally fins/inch

- 625” diameter coils 6 – 14 fins/inch

- 500” diameter coils 6 – 16 fins/inch

- 375” diameter coils 10 – 20 fins/inch

- All fins have a tolerance of +/- 4%

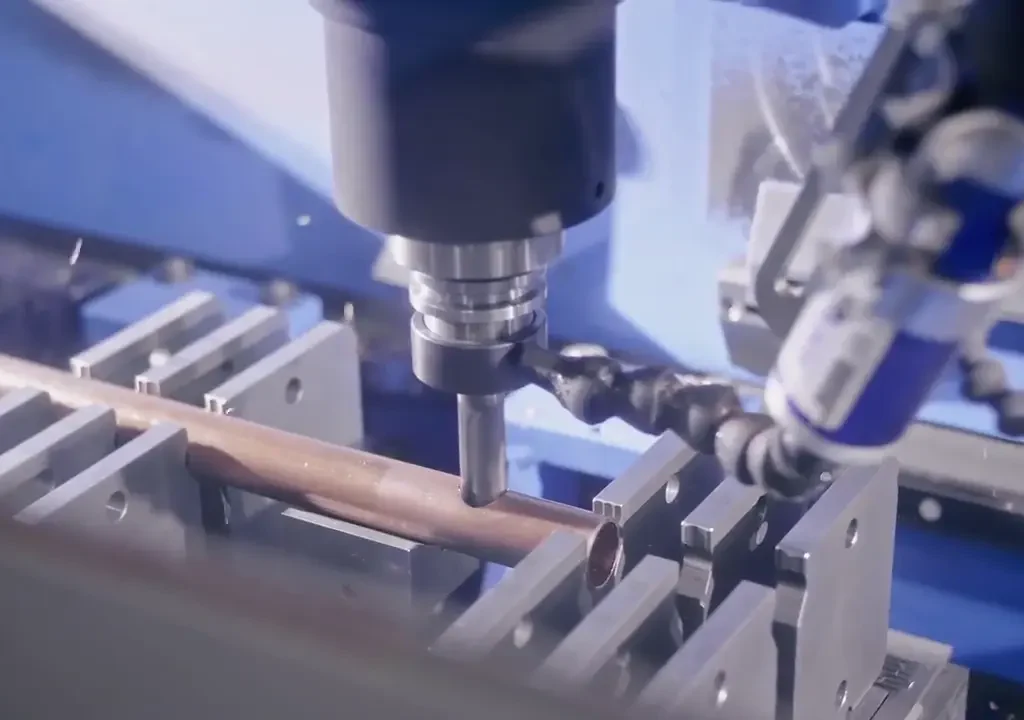

Tubing

- Tubing and Return Bends: Standard pressure, constructed from UNS12200 seamless copper conforming to ASTM B75 and ASTM B251.

- Copper Tube Temper: Light annealed with a maximum grain size of 0.040 mm and a maximum hardness of Rockwell 65 on the 15T scale.

- Tube Expansion: Mechanically expanded to form an interference fit with the fin collars without decreasing tube wall thickness.

Minimum Thickness

- 0.016” for 0.500” and 0.375” tubing

- 0.020” for 0.625” tubing unless specified otherwise

Casing (End Plates and Side Plates)

Shall be made from one of the following materials:

- Copper 0.093” thick meeting ASTM B152

- 16- or 14-Gauge, stainless steel meeting ASTM A240

- 16- or 14-Gauge, G90 galvanized steel meeting ASTM A653

Sheet Metal Breaks:

Bent to 90° +/- 2° unless specified otherwise. Formed tube collars are designed so that the expansion surface is 0.100″ and the ends are re-flared to prevent raw metal edge from contacting copper tubes.

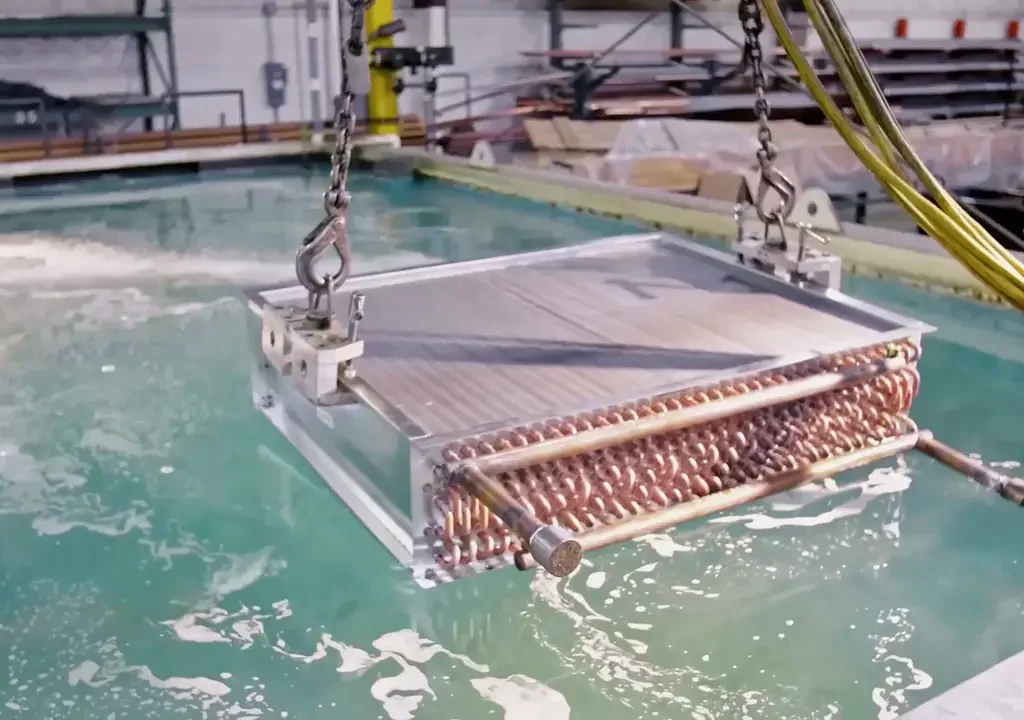

Testing Requirements

- Coils shall be submerged in water and tested with dry nitrogen.

- Water coils are tested to 450 PSIG

- Evaporator, condensing and steam coils are tested to 600 PSIG

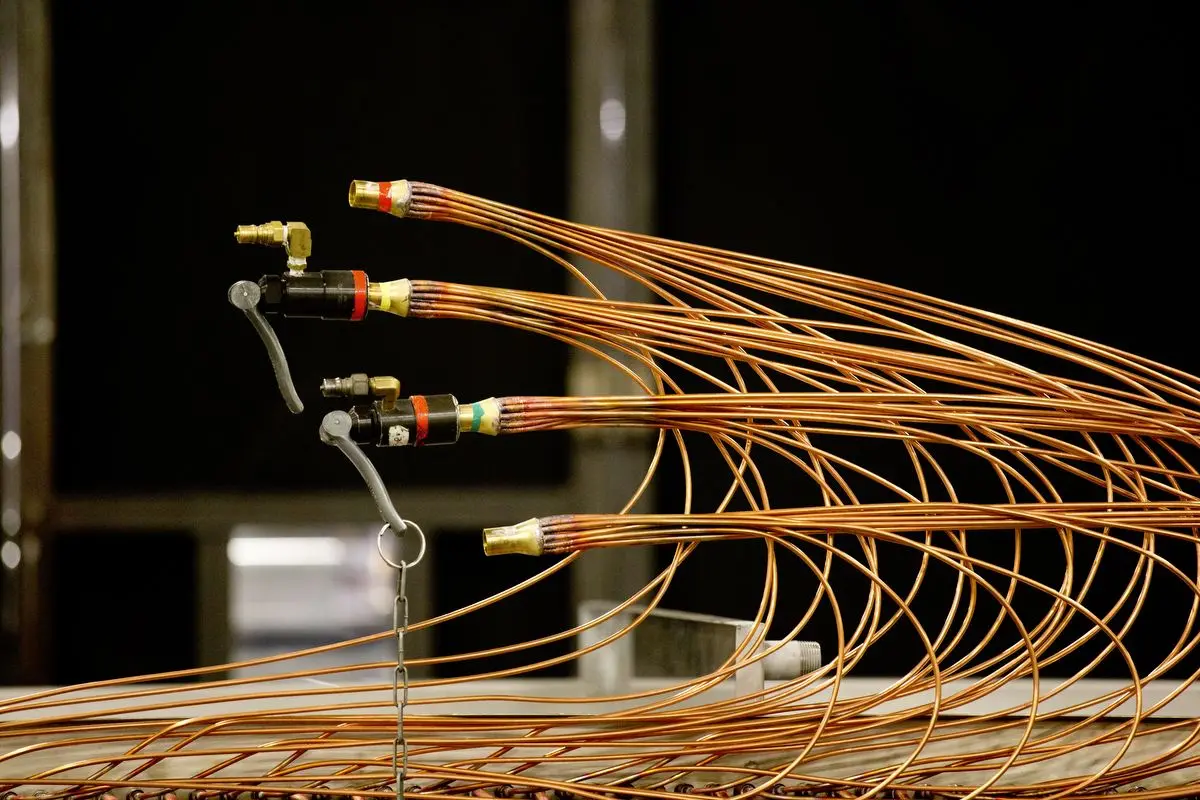

Headers

Headers shall be constructed from UNS 12200 seamless copper conforming to ASTM B75, ASTM B88 and ASTM B251.

- Water Coil Headers: Equipped with optional factory installed manual air vents and drains placed at the highest and lowest points.

- End caps (1.625″ and larger): Die formed and installed on the inside diameter of the header such that the landed surface area is three times the header wall thickness.

- End caps (Less than 1.625″): Flat copper sheet stock circle sheared, stamped or punched to header diameter and installed on the header ends.

Connections

- Male pipe thread (MPT) and constructed from red brass conforming to ASTM B43 or schedule 40 steel.

- MPT or female pipe thread (FPT) and constructed from copper

- Sweat connection constructed from UNS 12200 seamless copper conforming to ASTM B75 and ASTM B251.

Brazing

High temperature filler metals shall be used for all brazed joints. Filler metal will contain at least 5% silver.

Certification

Acceptable coils are to have AHRI Standard 410 certification and bear the AHRI symbol. Non-certified coils or coils outside AHRI ‘s rating range will be considered if the manufacturer is a current member of the AHRI air-cooling and air-heating coils certification program and the coils have been rated in accordance with AHRI Standard 410.

Right Fit. Right Now.